021 619 366

The Mincon Ring-Bit Systems use our patented Spiral Flush air-control technology to avoid damage or disruption in complex ground conditions or existing foundations, thus leading to safer drilling.

In large-diameter drilling applications energy transfer to the ground is significant, but Mincon’s DTH hammers have a high-frequency design that lets them operate above the nominal frequency of the ground. This technology mitigates excess ground vibration by cycling hammers above the natural harmonic frequency of the ground.

All Mincon Geotechnical products are manufactured to exacting tolerances using the very best materials and tungsten carbide buttons, ensuring excellent service life for serious contractors.

Our Geotechnical Drilling solutions are backed up by a global service footprint and highly experienced consultants with in-depth knowledge of Mincon products and cutting-edge geotechnical techniques.

Construction and Geotechnical Solutions

Mincon’s Geotechnical Drilling Ring-Bit Casing Advancing Systems offer solutions for a variety of construction techniques, including foundation drilling, pipe pile-walls, forepoling, well drilling, and anchoring.

SPIRAL FLUSH DESIGN

-

Flushing channels are crosswise to the drilling direction

-

Back flush creates a vacuum to the pilot bit face area

-

Air channels are above the ring bit cutting edge

CONVENTIONAL DTH DRILLING

Conventional DTH drilling has two problem areas:

-

Pressurised air over drills material. Over drilling removes more material than anticipated changing the ground’s original characteristics impacting nearby structures.

-

Air that is blown forward travels long distances in loose ground or soft clay. This can cause severe damage to nearby buildings and structures.

As a result, the use of conventional DTH drilling is limited already in several city centre's, shorelines and other sensitive areas around the world.

Integrated Ring-Bit Systems

Integrated ring-bit systems are designed for drilling straight piles through boulders, rock layers, and even into inclined bed rock.

The heavy-duty ring-bit is integrated in the casing shoe, making it safe to drill in loose ground and water.

PRIMARY APPLICATIONS:

-

End-bearing piles including micro-piling

-

Pilings with sacrificed casings, which have

no large ID ring-bit requirements -

Slope stabilisation

-

Pipe walls, king piles

Solitary Ring-Bit Systems

Solitary ring-bit systems are designed for drilling end-bearing piles through boulders, rock layers, and even into inclined bed rock.

The heavy-duty ring-bit is not attached to the casing shoe, making it the most economical ring-bit solution.

PRIMARY APPLICATIONS:

-

End-bearing piles including micro-piling

-

Pilings with sacrificed casings, which have

no large ID ring-bit requirements -

Slope stabilisation

-

Pipe walls, king piles

Large ID Ring-Bit Systems

Large Inner-Diameter (LID) ring-bit systems are used with sacrificed casings when there is a requirement to continue the hole after the casing is set.

Such casings are left in the ground for economical reasons, corrosion protection, sealing, or dealing with ground cavities.

PRIMARY APPLICATIONS:

-

Piling with sacrificed casings and rock sockets

-

Geothermal and Water Well's

-

Surface Casings (sealing, dewatering)

Drill-Through Systems

Drill-through ring-bit systems combine conventional rock-bit and casing-advancing systems.

Overburden can be drilled with ring-bit set, and then the pilot bit is unlocked from the ring-bit to drill a rock socket without the need to change tools.

PRIMARY APPLICATIONS:

-

Anchoring applications

-

End-bearing piles with rock socket

M-Wall Ring Bit Systems

Solitary M-Wall ring-bit systems are used to drill straight, interlocked casings through boulders, rock layers, or inclined bedrock.

With this technique, it’s possible to build interlocked casing walls, roofs, and other structures for the construction industry. M-Wall piles can also replace sheet piles and slurry walls in rocky ground conditions.

The heavy duty ring-bit is not attached to the casing shoe, making it the most economical of the ring-bit solutions.

PRIMARY APPLICATIONS:

-

M-Wall pipe-pile walls

-

M-Wall pipe-pile roofs

-

Cofferdams

-

Retaining Walls

-

Water-tight cut-off walls

Integrated M-Wall Systems

Solitary M-Wall ring-bit systems are used to drill straight, interlocked casings through boulders, rock layers, or inclined bedrock.

With this technique, it’s possible to build interlocked casing walls, roofs, and other structures for the construction industry. M-Wall piles can also replace sheet piles and slurry walls in rocky ground conditions.

The heavy duty ring-bit is not attached to the casing shoe, making it the most economical of the ring-bit solutions.

PRIMARY APPLICATIONS:

-

M-Wall pipe-pile walls

-

M-Wall pipe-pile roofs

-

Cofferdams

-

Retaining Walls

-

Water-tight cut-off walls

Horizontal Ring-Bit Systems

Horizontal Ring-Bit Systems are made for horizontal drilling of utility lines. High-friction casings call for a heavy duty ring-bit system.

Drilling under roads and railways requires advanced air control. Thanks to a reliable design, Mincon’s ring-bit system can be used over and over.

PRIMARY APPLICATIONS:

-

Horizontal drilling of utility lines

-

Road & railway underpasses

-

Replacing of concrete culverts

-

HDD surface casings

-

All break through drilling

Forepoling Systems

Forepoling ring-bit systems (also known as tube umbrella systems) are designed to be drilled with a Top Hammer or DTH in an umbrella shape, as secondary support in a tunnel roof, allowing weak ground or overburden to be strengthened by grouting through the casing and grouting valves into the ground.

PRIMARY APPLICATIONS:

-

Forepoling or tube umbrella

-

Anchoring

-

Micro piling

-

Fibre glass face stabilisation

-

PVC foundations

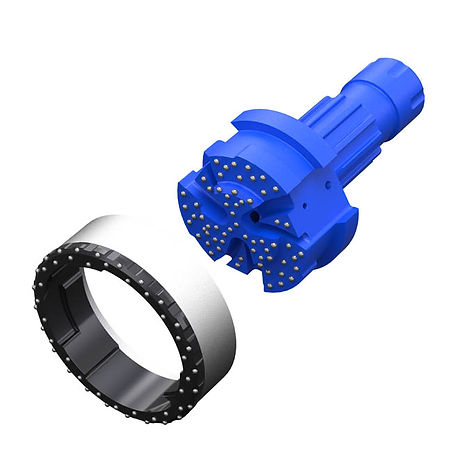

Large Diameter Rock Bits

Mincon's large-diameter rock bits are purpose-engineered for each customers individual requirements. Their concave structure gives them excellent accuracy in challenging jobs with high demands for hole straightness. Mincon's large-diameter rock bits have been used for a variety of applications, including air ventilation for tunnels; shafts for utility lines; rescue shafts for mining, and rock sockets in construction.

-

Large diameter rock bit sizes: 300mm - 1,750mm

-

Supported Shanks: All major shanks and Mincon shanks

Retrievable Ring-Bit Systems

Retrievable ring-bit systems can be reused several times and are designed so that the casing can always be pulled out after drilling.

A large inner diameter allows for the largest rock socket and installed elements.

PRIMARY APPLICATIONS:

-

In-situ piles (skin friction) where casing is fully retrieved

-

Anchoring applications

-

Pre-drilling / temporary casing applications

-

Energy / Water Wells where casing is fully removed